The olefins industry is a cornerstone of the petrochemical sector, producing essential feedstocks like ethylene and propylene that form the foundation for manufacturing plastics, synthetic fibers, and various industrial materials. With the rising global demand for consumer products, the industry is set to experience continued growth.

Traditionally, olefins are produced through steam cracking of hydrocarbon feedstocks such as naphtha and ethane. However, technological innovations are enabling more energy-efficient and sustainable methods, including catalytic cracking and the use of bio-based feedstocks.

As regulatory pressures intensify, the olefins industry faces the dual challenge of adopting cleaner technologies and optimizing operational efficiency. The transition to greener production pathways offers significant opportunities while requiring the industry to balance growing demand with environmental responsibility.

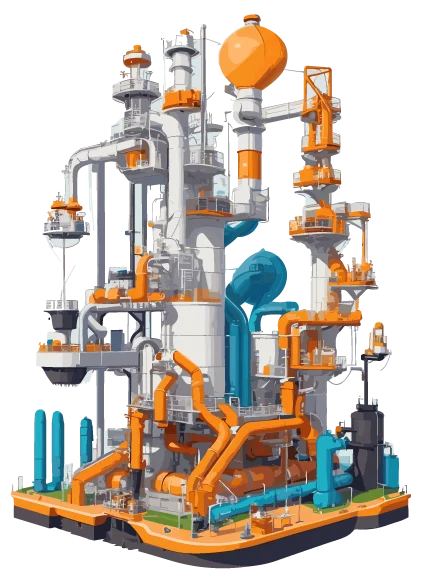

Olefins

Our key offerings for the Olefins Industry

Advanced Process Modeling

We provide modeling and simulation for steam crackers, with detailed feedstock analysis. Rigorous reactor models are calibrated to real conditions, ensuring accurate performance insights and predictions.

Dynamic Simulation Models for Operator Training

We create dynamic simulation models to mimic cracker operations. These provide real-time insights, helping operators gain the skills needed to manage complex scenarios with confidence and efficiency.

Planning with LP Submodels

We design reduced-order LP submodels for steam crackers. These simplified yet powerful tools integrate seamlessly with planning systems, enhancing decision-making in refineries and petrochemical workflows.

Adoption of Advanced Technologies

Our studies facilitate the adoption of innovative solutions like catalytic cracking and bio-based feedstocks, helping clients explore sustainable and forward-thinking technologies.

Strategic Advisory for Sustainable Growth

We guide clients on adopting renewable feedstocks and reducing carbon emissions, enabling a smooth transition to greener production methods and long-term sustainability.